The Best CNC for Small Shops | Shapeoko 5 Pro Review

Best CNC Machine For Small Wood Shops?

This is the Shapeoko 5 Pro CNC from Carbide 3D is quite possibly the best CNC for most garage shops.

Buy a Shapeoko 5 Pro Here - https://collabs.shop/xd9ye9

VFD Spindle Kit - https://collabs.shop/0v5jyg

In this review I’ll cover 5 main takeaways from my Shapeoko experience so far.

Shapeoko 5 Pro Assembly Process.

What I think about using the Shapeoko 5 now that I’ve had it for a several weeks.

Shapeoko 4 vs. Shapeoko 5 and why the 5 is the better machine in my opinion.

What I don’t like about the Shapeoko 5 Pro and a few points that I really do like.

Must-have CNC bits you should have.

The links to the tools in this review can be found at the bottom of this post. Affiliate links are used on this website to help support the website. For more information, read our affiliate disclaimer.

Packaging – I opted for the Shapeoko 5 Pro 24” x 48”. You can get one size smaller in a 24x24 or one size larger in 48x48. My machine shipped in two very large boxes, and they are quite heavy. When you first open the boxes, you’ll notice how well this equipment is packaged. It’s not going to get damaged in transit, even if it gets bumped around a little bit. It’s packaged in some nice foam inserts. The main thing I appreciate about Carbide 3D is how each box is well labeled, from “Open First” to “Assembly”.

#1 - Assembly – Assembly went quickly, which is one thing that’s been improved in the Shapeoko 5 Pro vs. the 4 XXL. The Shapeoko 4 took quite a long time to assemble, and they’ve refined that process here. Where you might find yourself slowing down a little bit is putting in all of the screws into each piece of the hybrid table, unless you have a kid or significant other you can trick into doing this for you. You don’t want to use a power tool here because you don’t want to strip things out. It's made out of aluminum, and it will strip out easily if it’s over-tightened.

I messed up during the assembly. Fast forward to a couple of days later, and I messed up. Apparently, I threw away or misplaced the cable that operates the spindle. I reached out to Carbide 3D support, told them what happened, and they shipped me out a new cable, no questions asked. Thank you, Carbide 3D. This is their policy. 30 Days Mistakes are On Us.

You may notice when you take everything out of the boxes that you received everything you need to get started using your new CNC. That’s one thing that Carbide 3D has done well. You get clamps, you get the dust boot, you get the hybrid table, and they even include a bit so you can get started right away. A lot of competitors leave out important things, like the table.

Speaking of the table (or bed) I really do love this table set up. It has standard t-slots in it, and they include t-nuts and bolts so you have everything you need to clamp down your work. It’s really well thought-out in my opinion.

#2 – Thoughts on Use – For the first job on the new CNC I made one of the baseball trays that we sell in our store. It has an American flag intermixed with a baseball. It’s a really cool-looking tray. I didn’t do anything with the file before uploading it to the new machine. It’s the same file I was using on the Shapeoko 4. All I did was set my zero and load my file.

The noise level of the Shapeoko 4 was extremely loud, especially the router. On the Shapeoko 5, I’m using the VFD spindle, and it is significantly quieter. Most of what I hear are the ball screws or the motor itself, not the actual spindle. It’s impressive.

After a couple of weeks of use, I’ve been able to really batch out a lot of stuff faster than I was able to before – guitar trays, baseball trays, and of course our mallet templates that we sell in our online store. The CNC has really opened up a world for us as far as the business goes because this has allowed us to make those things here in a garage shop. This thing works extremely fast compared to the 4 XXL. I may have had those speeds set a little conservatively, but I’ve really been able to push things, and it’s really impressed me.

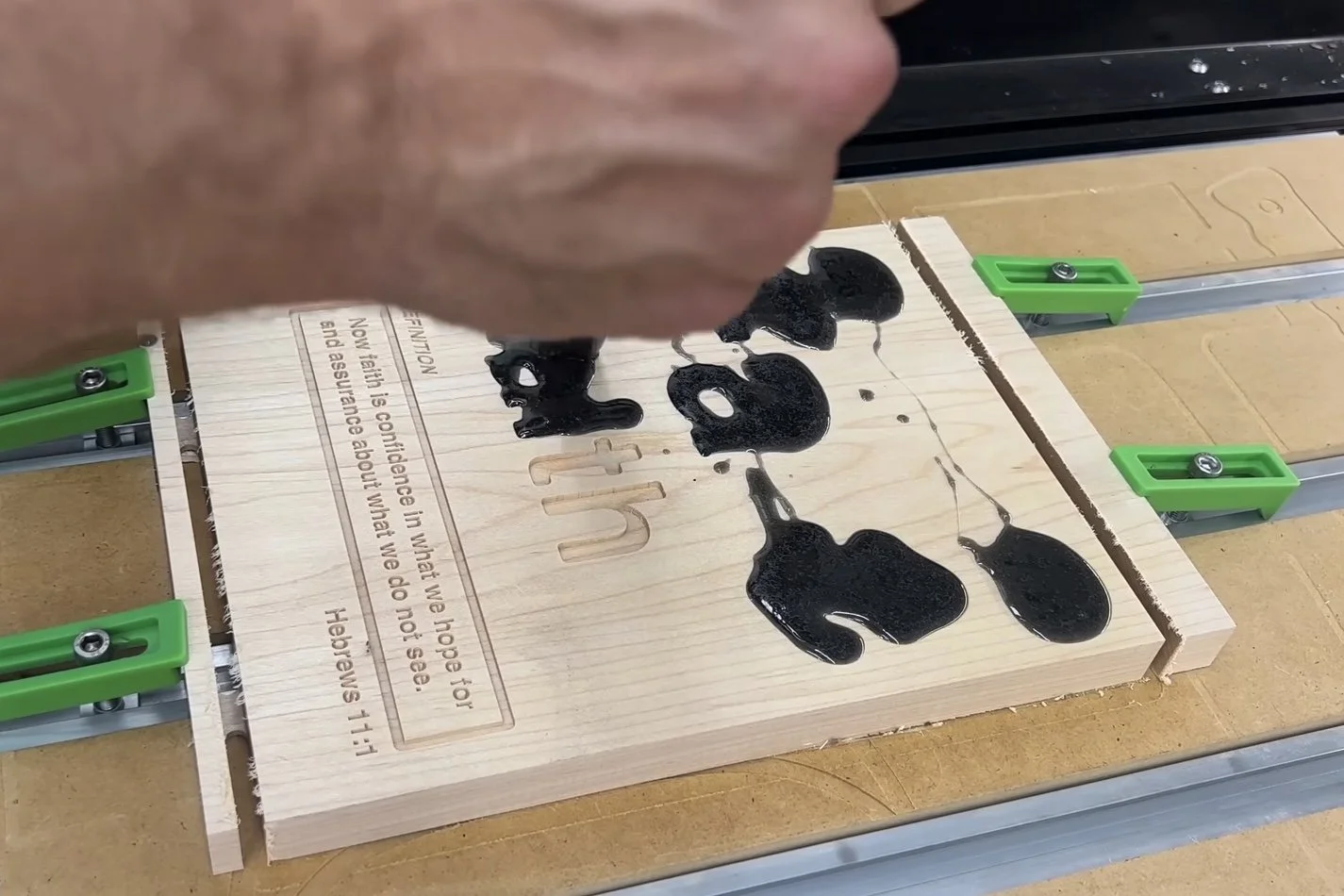

I was even able to make my wife a custom retirement sign and then filled those engravings in with epoxy. That’s what I love about the CNC. I had an idea, put it into the software, sent it to the machine, and made it. She loved it. It was a great retirement gift for her.

One thing I’ve been impressed with is the fine details and how nice things are coming out, like on the lettering I did on my wife’s retirement gift. The lettering is fairly small and detailed. The stars on our baseball tray look nice and crisp. Carbide 3D has made a lot of nice stuff in their own facility with some very fine detail work as well. As far as accuracy and precision with a Shapeoko 5, you won’t have any issues.

In terms of complexity in operating the machine, Carbide has done an excellent job of putting you at ease with using their machines. They have their own FREE training you can get. You can actually do that now before you buy the machine. Just download the free software and start working through the courses at https://my.carbide3d.com/. That’s a good way to get you started with CNC and it takes away the barrier to entry for these machines.

One thing people get nervous about on a machine like this is messing something up. The bed has MDF inserts that are meant to be cut into, you can replace those easily with ¾” MDF. Your bits are going to get into that. It’s called a waste table for a reason, so don’t let that concern you. Mine are engraved with the guitar trays where I had it set just a little too deep. That’s what they are there for, so don’t worry about that.

# 3 – Shapeoko 4 vs 5 – Let’s start with a few features on the Shapeoko 5 Pro that weren’t on the 4. First and foremost, there’s an emergency stop button now. If this machine’s running, and something happens, all I have to do it hit that stop button and it stops everything. That’s handy if you have a setting wrong, or you programmed something wrong. To restart it, you just turn that stop button until it pops back up, and the power’s back on.

I’ve got the VFD spindle, and this thing is fantastic. I would highly recommend picking this up if it’s in your budget. It’s much quieter than the router was on the 4 XXL. It does have its own controller, which is wired into the main board, and all of that is controlled in the software. Once you set it up, and you’re ready to cut, the spindle turns itself on, and it turns itself off. This is a huge upgrade over the 4 XXL that I was accustomed to.

Another big upgrade is the ball screws. There’s no shaking or moving, it’s really well done. As far as setup goes, it was super simple to put together. The instructions were top-notch. The dust collector that I’ve got took longer to put together than this CNC machine.

One thing Carbide did that was really smart regarding the assembly process was with the wiring. All the wiring connections only have one matching connector. In other words, you can only plug each wire bundle connector into the corresponding connector it’s supposed to go with. In the previous setup with the 4 XXL, I had a little trouble from wiring things up wrong to begin with, so I’m glad they refined that process.

Another thing I absolutely love is that this machine has a 60” x 35” footprint. This is a much smaller footprint than the 4 XXL was. The 4’ x 2’ work surface is the ideal size for my garage workshop (and probably a lot of yours as well) just because it doesn’t take up as much floor space. If you need the bigger size, they certainly have the 4’ x 4’ available. I rarely cut anything that requires that much workspace. The 4’ x 2’ has an indexing feature, meaning you can still run full sheets of plywood through it if you needed to. There’s really no limitation other than having to index a couple of times.

The Shapeoko 5 Pro also has a bit-setter function. This will automatically zero your Z-axis every time, which makes life so much easier. My 4 XXL didn’t come that feature, so I was setting Z every time I changed bits. It was a nightmare. It comes with the 5 Pro, but if you get one of the other models, I would certainly add that on.

The underlighting can’t be overstated. That is an extremely nice feature. Being able to see your work is one of the best features they added to the 5 Pro. As simple of an add-on as it is, it’s just so much nicer.

Likes/Dislikes – One thing I wish is that Carbide offered the MDF inserts for sale individually or provided files to make your own with the CNC. It comes with 12 inserts, and I wish I could just buy a pack of them when I needed them instead of having to rip them down and then drill the holes to attach them to the table.

I also don’t really care for how loud the ball screws are on the X-, Y-, and Z-axis. I know that’s a little nit-picky considering this machine is already making noise, but those are actually louder than the sound of the spindle. If they could figure out how to quiet those down some in the Shapeoko 6, that would be a positive.

The main control board is a little loud as well. There’s a little fan in it and when the machine is running, you’re not going to hear it. However, when it’s sitting idle, it has a low hum. If that bothers you, there it is. If they could figure out how to quiet down those X, Y, and Z motors, this would be a very quiet machine to work with. You would literally be able to work in the shop without hearing protection.

Something I really like about Carbide 3D is their support. Anytime you call them, they’re going to get you what you need or help you in the best way possible. This isn’t just coming from me who’s working with them. I hear that time and time again from other folks who have just purchased the machine.

#5 – Bits & Accessories – If you’re just starting out with CNC, what bits do you need to get started? I’m going to list off the ones I think you really need. You’re going to get a ¼” endmill with this machine. I would go ahead and pick up at least two or three ¼” end mills. Those are my most used bits. I would also recommend picking up an 1/8” endmill. That will help you with some finer details-- pockets, things like that. If you’re wanting to get really fine detail like small lettering or small stars, then you’ll need a 30-degree v-bit. Most people starting out will need a 60-degree and a 90-degree v-bit. Last but not least, you’ll want to get a surfacing bit. With a surfacing bit you can flatten boards, slabs, and your epoxy fills. Using a surfacing bit on your epoxy fills makes finishing go much faster. Those bits will get you through 85% to 90% of what you’ll start out making. There’s a starter kit available that has most of these bits in it.

Also, if you’re getting a CNC, I recommend picking up a good quality caliper. I use one from Mitutoyo (just don’t ask me to pronounce it). It’s a very nice, accurate caliper. You’re going to need that to measure the thickness of your boards so that you can input it to the software and the machine knows how deep to cut. This is a must-have if you have a CNC.

I don’t think this machine is necessarily for everybody, but I do think it’s a good fit for a garage shop to make the kinds of things you’ve seen me making. If you’re in a large production shop, you need a giant CNC and this will not be a good fit. In a situation like that, you’re going to be investing thousands of dollars more than you would on something like this.

I’d also like to thank Carbide 3D for allowing me to give the Shapeoko 4 XXL to Noah.

*Tools in this Review

Buy a Shapeoko 5 Pro Here - https://collabs.shop/xd9ye9

VFD Spindle Kit - https://collabs.shop/0v5jyg

Shapeoko 4 XXL is the CNC - https://shop.carbide3d.com/731woodworks?redirect=/products/shapeoko4?variant=33051555987517

Starter CNC Bit Kit - https://shop.carbide3d.com/731woodworks?redirect=/products/shapeoko-cutter-starter-pack

1/4-inch end mill - https://shop.carbide3d.com/731woodworks?redirect=/collections/cutters/products/201-25-end-mill-cutter

1/8-inch end mill - https://shop.carbide3d.com/731woodworks?redirect=/collections/cutters/products/102-125-end-mill-cutter

CNC Surfacing Bit - https://amzn.to/3OKGeZx

30 Degree V Bit - https://amzn.to/42bzbfw

Digital Caliper - https://amzn.to/43cyu6U

Free CNC Training - https://my.carbide3d.com

Baseball American Flag design I got on Etsy: https://www.etsy.com/listing/996880655/baseball-flag-template-cnc-c2d?ref=yr_purchases

You can watch the full video review here - https://youtu.be/udFcuwckPZw

Greatest Free Gift I've Ever Received: http://story4.us/731Woodworks

Let me know what you think about the Shapeoko 5 Pro in the comments below.