SawStop Compact Table Saw Review

SawStop Compact Table Saw Review, Revisited

The SawStop jobsite table saw is the latest, the greatest from SawStop. It is a very expensive saw as far as jobsite saws go at $899 plus whatever taxes and shipping will be to you. I have a video of my first impressions, which you can see here - https://youtu.be/TieBJVT5nBM. This is an excellent saw. I’ve been highly impressed, except for the one thing I was sort of wrong about – the fence.

SawStop Compact Jobsite Table Saw -

(Tools Today) https://shrsl.com/3zer9

(Amazon) https://amzn.to/3Z0ivWD

Affiliate links are used on this website to help support this website. For more information, read our affiliate disclaimer.

I purchased this SawStop on a pre-order because I was excited to get it. When I got it, I was more than disappointed that the fence was less than what I thought it should be. At full extension, it had a little bit of slop. SawStop tech support sent me a PDF on how to adjust the fence to get that slop out. This does introduce a new problem, or a new annoyance I should say. It did fix the up-and-down play that was in the fence.

To adjust the fence and tighten that play up, it’s actually extremely easy. On all four corners there’s a cam. You loosen the bolt that’s inside that cam, and you turn the cam slightly until you get slack out of the fence. Once you have that done so that it’s snug on all four corners, you can run the fence all the way out, lock it in place, and the vertical movement is essentially gone. You could see what looks like the fence flexing a little bit, but that’s actually the entire saw flexing, tabletop and all. It’s not the fence.

Also, there are two pieces in the middle of both front and back of the fence, that are basically two wedges. You can loosen the bolt on those wedges and slide them apart, which creates another wedge inside the fence, and that tightens everything up. This gives you a super snug fit all the way across, as far out as you can extend the fence. Doing that, it works great now.

There is a minor annoyance that’s been introduced because you’ve tightened everything up. It’s now harder to move the fence back and forth, and the actual movement of the fence is quite a bit stiffer. It makes perfect sense that it’s going to do that, but there’s got to be a happy medium there or it just gets too hard to move. When I first tightened everything up, it was extremely hard to move. For the first few days of me using the saw, I really had to get down on it to make it move. Now it’s just slightly snug. That raises a few concerns, but we’ll get to that later.

First, I want to go through everything I like about the saw. One thing to note if you buy the saw, you may or may not have the fence issues that I had. Mr. Ron Paulk did a video on his channel, and when he got his saw, he didn’t have any issue at all.

So, what do I like about the compact jobsite table saw? I love the fence if it’s dialed in. What I really like about it is the rack-and-pinion. The DeWalt jobsite saw has rack-and-pinion also. What that means is that it’s gear driven. When you turn the knob, it’s connected to gears at both the back and the front. When you’re moving the fence, both the back and front are moving exactly the same. That keeps the fence nice and square to the miter slots and the blade.

Another thing I really like is how easy it is to adjust the fence to square it up should you need to. There are two different bolts on the fence rail that you can mount your fence on. Whichever one you’re using, you loosen the bolt with an allen wrench, make whatever minor adjustments you need, and you’re ready to go. With the blade square to the miter slot, and the miter slot square to the fence, everything is square to each other now.

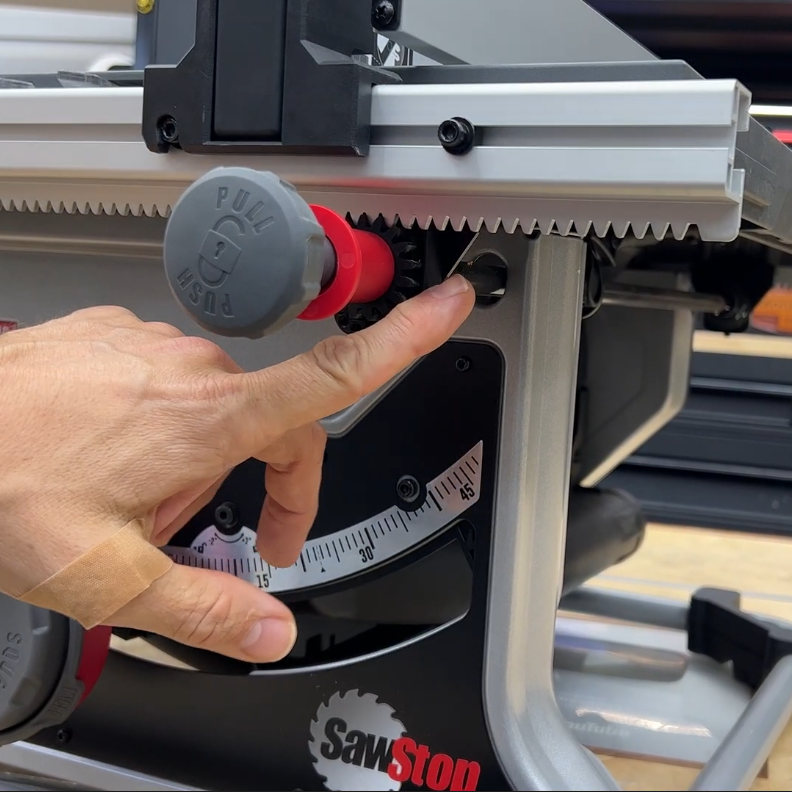

I really like how fast you can adjust the miter angle. You just pull on the handle in front, then it slides with ease to whatever angle you need all the way up to 47 or back to -2. You can also micro-adjust the angle by turning the dial on that handle.

Another thing I really like about SawStop is that it comes with a zero-clearance throat plate. That means you’re going to get a cleaner cut on plywood, soft woods, or hardwoods because you’re going to get less tear-out on the bottom. I also like that it’s heavy enough that it doesn’t move around on top of the workbench, but it’s not so heavy that you can’t move it around the jobsite, throw it in the truck, things like that.

Another very nice feature is the on-board tool storage. I haven’t seen any other saw like this. I’ve got the DeWalt, and it seems like an afterthought on the DeWalt. This was planned out. Everything is located in single kit on the back of the saw. Inside the kit you get your blade guard and a riving knife that you use with the blade guard and anti-kickback pawls. There’s already a riving knife on the saw for use without the blade guard. There’s also a miter gauge in the kit. If you’re like me, you forget how things go, but there’s pictures in the kit to let you know how to put everything back. There’s even a detailed instruction on what goes in first and last.

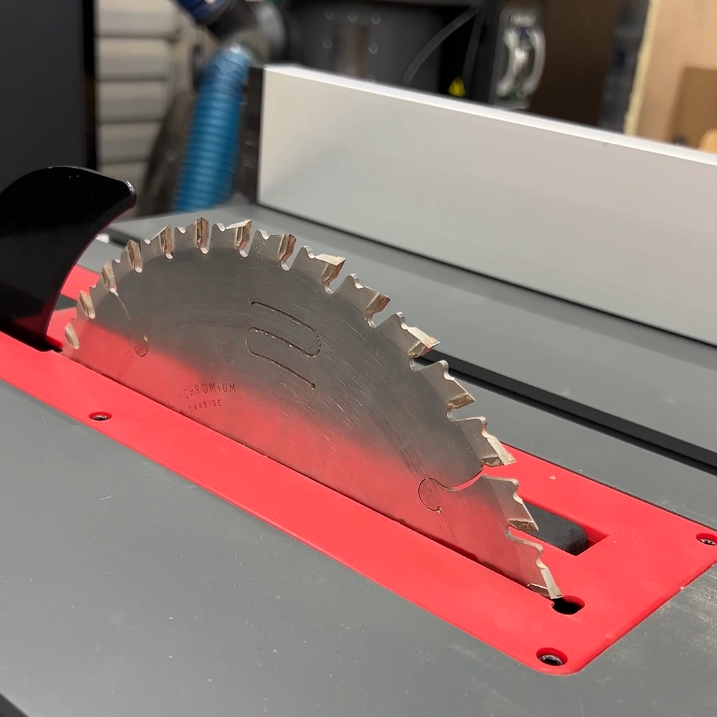

This is a full 10” blade, so you get that full cut-depth that you normally get on most bigger saws. As a matter of fact, it’s the same cut-depth as on my SawStop PCS.

Stock SawStop Blade isn’t great

I replaced the stock blade with a 24 tooth CMT Chrome blade.

Full depth cutting on the SawStop CTS is 3-1/8 inches at 90 degrees

I got a couple of questions on my first impressions review. One was will this accept a dado stack, and the answer is absolutely not. This thing is maxed-out with just a regular full-kerf blade on it, with no more room on the arbor.

Another question I got was why would you deactivate the safety feature, which you can. One reason is if you’re cutting wet or damp wood, or aluminum, you can trip the blade brake. When I touch the blade with my hand, the red light by the power switch starts flashing, letting me know the circuit has been completed, and it’s not going to let me turn the saw on.

SawStop CTS status lights under the power switch can sense when you touch the blade

After I adjusted the fence, I wanted to see how accurate the saw is. What I did was I took a piece of MDF, and I used the 5-cut method at about 9½”. On the 5-cut method, what you’re doing is cutting each of 4 sides the same distance away from the blade, rotating in the same direction after each cut. On the 5th cut after you rotate it, you move the fence a little closer to the blade so that you cut off a sliver from that piece. You then measure each end of your sliver, and that’s going to tell you how accurate your fence is to the blade. This one was dead-on at 9.44mm, and I don’t normally use millimeters.

Included SawStop Miter Gauge (left) a much better alternative is the Incra V27 (right)

Next, I wanted to extend the fence all the way out and cut a piece of MDF, just to see how accurate it was at full extension. It’s just under 20 5/8”. You actually do get 4” more of rip capacity by moving the fence over to the outside bolt on the fence rail. The full-extension cut was dead-on. That proves to me that the saw is accurate at any length. The original fence issue is now a non-issue.

SawStop CTS Dust Port

This saw will cut through most anything you’re going to throw at it. I’ve cut walnut with it. I’ve cut pine, MDF, spruce, and had no issues at all. The saw has plenty of power to do what you’re asking it to do without bogging down.

Dust collection is done with 2¼” hose, so if you’ve got a shop vac or something similar, it’s going to connect right in there, which is perfect for most jobsites. If you even care about sawdust on the jobsite.

After having this for a couple of months and using it on a few projects, I can tell you this is a very good saw. So, who’s going to buy this at $899? Number one is the person who’s concerned about their safety. What you’re paying for is the safety feature. Also, this is a very well-built saw. The only thing I would be concerned about is if the fence is extended all the way out, the rails are just thin aluminum. If you flipped it over, if it fell out of the bed of a truck or off of a sawhorse, the fence rails would likely bend. Pretty much any jobsite saw’s built like this.

SawStop CTS High / Low Fence

A feature I like, but I wish was better is the high/low fence. You can flip the low portion over and to create a low fence if it’s next to the blade, and you can drop it down one more notch to be a work support when you have the fence extended. There is one thing I would really like them to change on it in future iterations. When you flip that low fence back over to store it away, there’s a metal clip to hold it in place. The clip on one side of mine broke the first day I had it.

SawStop CTS Status Lights

I do like the fact that there’s a sticker on the side that tells you about the status lights of the power indicator. I like that the throat plate has six adjustment points so that you can really dial that in and get it perfectly flush. Most jobsite saws only have four, and while that works okay, I just think it’s better when you have more ways to adjust it. This throat plate is extremely solid; it doesn’t flex or bend in the middle like on some other jobsite saws.

The blade brake is easily accessible should you trip the safety feature. It’s a good idea to have an extra blade brake in the shop just in case.

Plenty of power to cut through solid walnut

Overall, if you’re in the market for this saw, I don’t think you’ll be disappointed. In my previous review, before I got the information on how to adjust the fence, you can take that with a grain of salt. I wish that information had been included, but now that I know it can be adjusted, I think this is a solid buy. If you’re after a saw with the safety feature, this is the cheapest SawStop you can buy. If you’re not after that safety feature, I’ll be doing a review of the DeWalt jobsite saw soon.

You can watch the full video review here - Click here to watch the full review video

Related Articles:

5 Table Saw Jigs for Safer Cuts

First 5 Power Tools Every Beginner Woodworker Needs