Best CNC Machines for Small Woodworking Shops in 2025 (Beginner to Pro Picks)

If you’ve been thinking about adding a CNC machine to your small woodworking shop or garage, you’re in for a treat. CNCs aren’t just for big commercial shops anymore — they’re more affordable, easier to learn, and more compact than ever.

In this guide, I’m going to walk you through three top CNC brands — Shapeoko, Next Wave, and OneFinity — and help you figure out which model best fits your budget, space, and project goals. Whether you want to start carving signs in your spare bedroom or you’re ready for a full 4x8 machine in your garage, you’ll find your perfect match here.

Affiliate Disclaimer:

This post contains affiliate links, which means I may earn a small commission if you buy through them—at no extra cost to you. It helps keep the tool deals coming, so thanks for your support! Prices are valid at the time of posting but are subject to change at any time.

Why CNC Belongs in Your Shop

CNC machines open up a whole new world of woodworking. They can:

Cut precise parts over and over without measuring twice

Create intricate carvings and inlays you could never do by hand

Save time on repetitive cuts so you can focus on creativity

Expand your ability to sell unique, high-value projects

And with today’s compact designs, you don’t need a dedicated warehouse — you can run one in a one-car garage or even on a sturdy workbench.

Shapeoko CNC Machines — Complete Solutions for Small Shops

Links:

I’ve been partnered with Shapeoko for years and run one in my own shop. Here’s why I love them:

Multiple sizes (4x4, 4x2, desktop Nomad) to fit your shop space

Comes with everything you need — bed, dust collection, bit setter, software

Nomad is perfect for ultra-small spaces — pull it out of the box, plug it in, and start making

Whether you want to carve a full door on the 4x4 or mill aluminum parts on the Nomad, Shapeoko gives you the flexibility and support to get started fast.

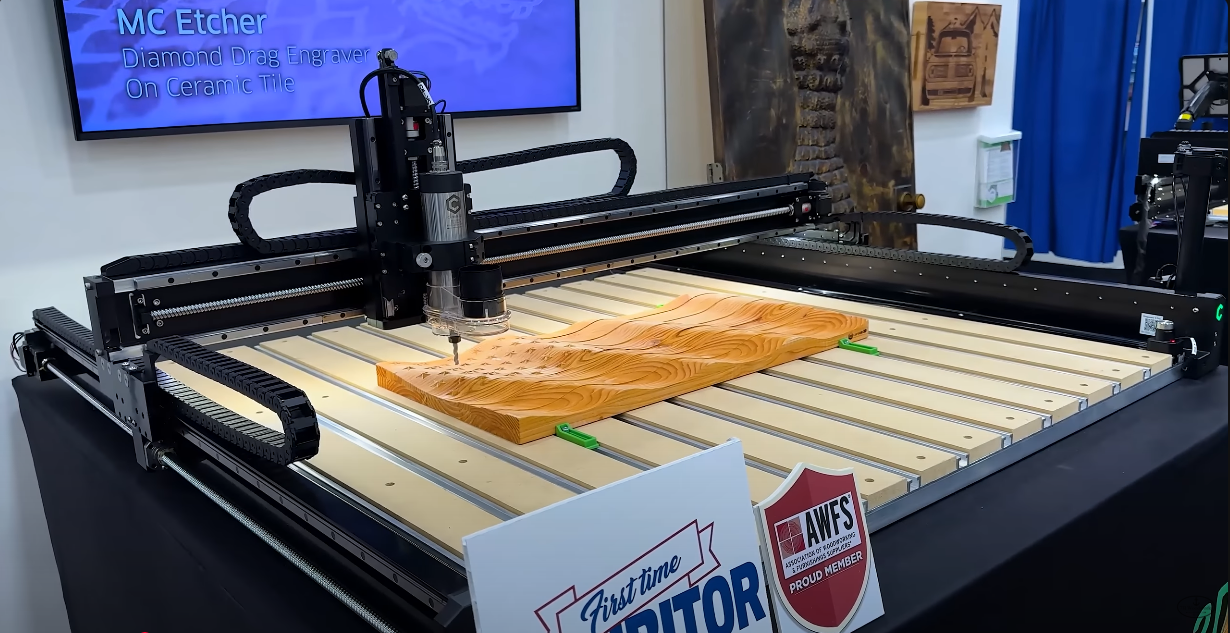

Next Wave CNC — Power and Precision in Multiple Sizes

Links:

Next Wave CNC has a model for just about every shop:

HD510 with 2x2 cutting base and water-cooled spindle

HD520 for double the length (2x4 capacity)

Smaller SD series for tight spaces

Flagship 4x4 with closed-loop motor system that keeps your position even if you hit a clamp

These machines are fast (up to 800 inches per minute, aiming for 1,000 soon) and come with serious upgrades like a 10.1-inch pendant, vacuum pod system, and 3HP spindle. If precision and reliability matter to you, Next Wave is a top contender.

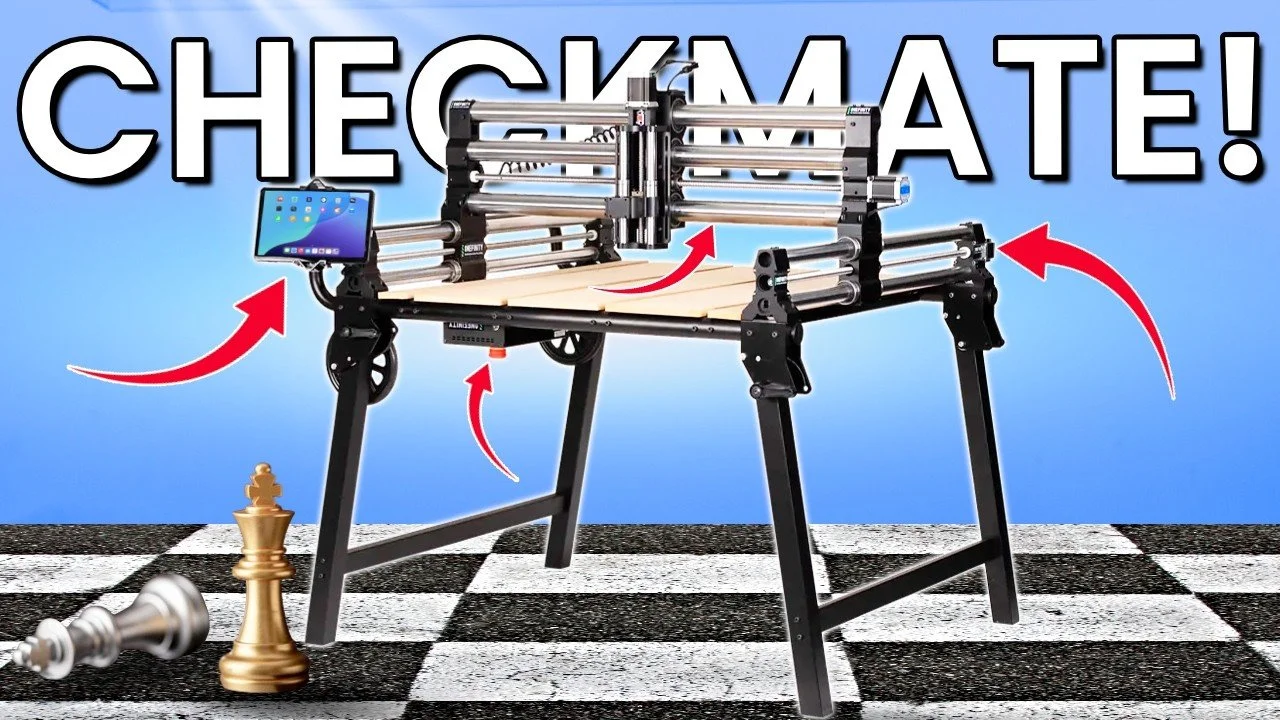

OneFinity CNC — Modular, Upgradeable, and Built Like a Tank

Link: OneFinity CNC Machines »

OneFinity is all about rigidity, precision, and expandability:

Beefy 7mm-thick rails and ball screws for ultra-precise cuts

Modular design lets you upgrade without buying a whole new machine

Elite Foreman 4x4 with closed-loop stepper motors to resume cuts after power loss

New “Full 8” moving bed upgrade turns a 4x4 into a full 4x8 CNC without taking up the floor space of traditional 4x8s

They also offer a powerful J-Tech diode laser add-on (up to 64W), a rotary axis, and a slick new Redline controller with a matte, easy-to-read touchscreen. This setup is perfect for serious makers who want pro features in a garage-friendly footprint.

Handheld CNC Option

If you want CNC flexibility without dedicating space to a full machine, check out this Handheld CNC Machine ». It’s portable, easy to store, and still gives you the accuracy CNC is known for.

My Advice for Choosing Your CNC

Match the machine to your space – Measure twice, buy once. If you’ve got wall space but not depth, the Shapeoko 4x2 or a Next Wave SD model could be perfect.

Consider your projects – Sign making, furniture parts, metal work? Your material and project size will drive your choice.

Plan for dust control – CNCs create fine dust that needs proper collection for safety and finish quality.

Think about growth – Modular machines like OneFinity let you start small and expand without replacing your investment.

Stay Safe While CNC Woodworking

Even though CNC machines are automated, you still need to follow safe woodworking practices:

Always wear hearing and eye protection

Use proper dust extraction

Secure your workpiece before cutting

Never leave a running CNC unattended

Conclusion

CNC machines are no longer out of reach for small woodworking shops. Whether you go with the complete ease of a Shapeoko, the pro-grade power of a Next Wave, or the rugged upgrade path of a OneFinity, there’s never been a better time to jump in.